By David Vergun, ARNEWS

Full-pace, full-scope testing of the Joint Light Tactical Vehicle (JLTV) prototypes began Sept. 3 and will last for 14 months.

Three prototypes vying to be the U.S. military’s Joint Light Tactical Vehicle are undergoing testing. One will emerge as the winner. The AM General prototype is on the left, Oshkosh JLTV in the center, and the Lockheed Martin prototype is on the right.

Each of the three vendors — Oshkosh Defense (Light Combat Tactical All-Terrain Vehicle [L-ATV]), Lockheed Martin (JLTV), and AM General (Blast Resistant Vehicle – Off road [BRV-O]) — delivered 22 vehicles and six trailers for testing to three sites: Aberdeen Proving Ground, Md.; Yuma, Ariz.; and Redstone Arsenal, Ala.

Rigorous reliability testing over various terrains and in different weather conditions and protection-related testing is being conducted, said Col. John Cavedo, the Joint Program Office manager, who spoke Sept. 4 during a JLTV webcast.

Reliability, availability, and maintainability, called RAM testing, will determine the winner, Cavedo said. Additionally, input from Soldiers and Marines “will absolutely be taken very seriously.”

RAM testing includes evaluations of performance, protection, and payload. The vehicles will also be evaluated for transportability, mobility, expeditionary capability, network-readiness, and affordability.

While this marks the beginning of full-scale testing, a certain amount of testing has already been done, including more than 400 ballistic and blast tests on armor testing samples, underbody blast testing, and more than 1,000 miles in shakedown testing.

The program is still on track despite this year’s sequestration and continuing resolutions, but if budget issues are not resolved by next year, Cavedo said he could not rule out a slip in the schedule.

“We’re doing everything we can to keep the program on track,” he said, emphasizing the importance of the program to meeting asymmetrical threats like those experienced in Iraq and Afghanistan.

Closing the capabilites gap

Cavedo related an incident years ago at the Fulda Gap on the East-West German border.

“My company commander pointed to the northeast and told me, ‘That’s where the enemy will come from,’ and then turned around and said, ‘That’s the secure area in the rear where the friendly forces will be.'”

During Cold War-era exercises, Humvees safely moved about the rear area while tanks and other heavily armored vehicles would maneuver in the battle space. The Fulda Gap was considered by many to be the best line of approach for Soviet tanks moving west and south.

That notion of front lines and rear area was no longer applicable after 9/11, he said. Humvees became vulnerable to improvised explosive devices no matter where they were. Up-armor was added for protection, but the enemy adapted to that with more lethal explosives.

The added weight of the up-armor taxed the Humvees’ performance and further limited its payload, which now included network gear. And the Humvees were just getting old, with the first ones rolling off the assembly line about three decades ago.

Oshkosh Defense’s Joint Light Tactical Vehicle prototype negotiates the off-road demonstration course at the Transportation Demonstration Support Area in Quantico, Va.

Soldiers and Marines continued to be vulnerable, so the mine-resistant, ambush-protected vehicles, known as MRAPs, were developed. These had good payload and protection and helped save many lives over the last six years, but performance was sacrificed and Soldiers could not move with speed and agility around the battlefield, especially in the difficult terrain in parts of Afghanistan, he said.

Furthermore, the heavier versions of the earlier MRAPs could not be moved around the battlefield by helicopter. They required strategic lift, which in turn required adequate runways for these big cargo planes to take off and land.

The sustainment cost for the MRAP program increased over time, he said, as more variants were developed by different vendors. Parts were not interchangeable, and mechanics had to get follow-on training, he said.

The JLTV closed the capability gap, addressing “the iron triangle of payload, performance, and protection,” he said. Its payload and protection is similar to an MRAP, and its performance exceeds that of a Humvee.

Adaptability and flexibility

Besides addressing the “iron triangle,” Cavedo said the JLTV is designed to meet the needs of the commander for a variety of missions.

The commander can decide what level of protection JLTV needs for the mission, he said, pointing out that armor kits will be available for vehicles going into harm’s way. Also, some of the JLTVs will be equipped with heavy weapons, including TOW missile systems, while others can be used as light utility vehicles.

Other kits include command and control and network gear. He said JLTV plug-and-play, open-architecture technology allows for future networks and electronic devices to be installed without a vehicle redesign.

Lockheed Martin’s Joint Light Tactical Vehicle prototype negotiates the off-road demonstration course at the Transportation Demonstration Support Area in Quantico, Va.

While different vehicles will have different kits, all vehicles come equipped with automatic fire extinguishers, multiple egress options, fuel-tank fire-suppression systems, and combat locks. Exportable power is also a key feature, with 10 kW being the minimum requirement and the top potential being 75 kW.

Powering the 14,000-lb curb weight JLTV and whatever kits and trailers are added on is a 300-hp fuel-efficient diesel engine. JLTVs also will be able to tow the thousands of legacy trailers that are still usable.

“We expect to see a 10- to 15-percent improvement in fuel economy just by going to a modern fuel-injected, digitally controlled engine and have a curb weight that still meets Army and Marine Corps mobility requirements,” Cavedo explained. “The JLTV will be designed with enough on-board power to support the Army’s future network and be able to take advantage of the latest generation of diesel engine technology to maximize fuel economy.”

Lockheed Martin’s JLTV overview demonstrates the primary goals/features of the vehicle and program.[Image: Lockheed Martin]

The JLTV is being built as a single truck in two primary configurations: a four-door platform called the Combat Tactical Vehicle and a two-door platform called a Combat Support Vehicle; the four-door platform will include a heavy gun carrier and close-combat weapons carrier variants designed to carry weapons such as a .50-cal machine gun, TOW missile, and conduct mounted patrols and convoy escort missions, among other things. The Combat Tactical Vehicle will be able to carry 3,500-lb of payload.

All of the JLTVs will be configured with Variable Ride-Height Suspension, described as the ability to raise and lower the suspension to meet certain mission requirements such as the need to raise the suspension in high-threat areas and lower the suspension so that the vehicles can be transported by Maritime pre-position-force ships. Also, the JLTV will be able to sling-load beneath a CH-47 helicopter under standard conditions.

Holding costs down

“We’ve managed to hold costs down by promoting better competition between vendors, incentivizing productivity, and conducting an analysis of alternatives,” Cavedo said. By “analysis of alternatives,” he means ordering the right number of kits and mission packages. “We don’t want surplus kits stockpiled in warehouses across the country.”

Incentivizing productivity, he explained, means that after giving the original equipment manufacturer, or OEM, the specs (like protection, speed, weight, and so on), it is up to them to determine how it’s built and what the tradeoffs are.

Cavedo provided an example. Besides armor kits, the basic JLTV requires a certain level of protection. There might be very exotic metals out there that are lightweight and offer exceptional protection, but the cost involved would be astronomical. So a tradeoff might be reached where steel or aluminum is used to keep the cost down but still meet the basic requirements. To be competitive, however, the thickness or type of material used might exceed basic standards but be within a reasonable price range.

AM General’s Joint Light Tactical Vehicle prototype negotiates the off-road demonstration course at the Transportation Demonstration Support Area in Quantico, Va.

Tradeoffs like this apply to the power and transmission features and to everything else on the vehicle, he said. They’re trying to be as innovative and competitive as possible with the other OEMs, yet they must stay below the $250,000 assembly-line figure.

There are other ways cost has been controlled. Instead of requiring each OEM to supply 35 vehicles, they were required to provide 22 for the testing phase, he said. That number is reasonable and adequate for an effective evaluation.

Also, instead of a cost-plus type contract, the JLTV is on a firm-fixed price contract.

“In the past, the production price was set after down-select,” he said. Down-select is the final selection of a single OEM vendor. “Our intent was to set production prices during competition, so as we go forward into the competitive down-select we’ll have production prices set at that point and not negotiated for the years out.”

“All three vendors absolutely meet the key requirements; all could close that critical and substantial capability gap in our light tactical wheel portfolio,” Cavedo concluded. “In the end, the government will pick the very best of best. We’re in a fortunate situation.”

Timeline

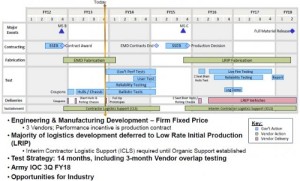

Source-selection evaluation will start in early 2015 and conclude by July of that year, when a single vendor will be selected.

At that time, 2,000 vehicles will be produced and tested for three years with the focus on fine-tuning the assembly line, full-up system testing, and so on.

Full-scale production will begin in fiscal year 2018 with the ratio of organic to contract work determined by the third quarter of fiscal year 2015.

By 2018, the first Army brigade will roll with new JLTVs, Cavedo said.

JLTV program schedule.

Production will total 49,000 JLTVs for the Army and 5,500 for the Marines, with the production cycle ending sometime in the 2030s.

Kits will initially be produced by the selected OEM, but follow-on kits might use a different vendor, he said.

In conclusion, Cavedo said the JLTV comes at the right time at the right cost; is the perfect match to the Army’s shift to the Pacific, regional alignment strategy; and meets the requirements of the Defense Strategic Guidance of 2012 and the Army’s 2014 Equipment Modernization Plan.